Hahahaha good thinking! Imagine a job interview and you get asked about these project names

This evening I tried to remove a stuck nut from an axle. The nut would spin but would not move vertically, because the threads both on the nut and axle were stripped. I wanted to get them apart because they were stuck in a wheel rim with a usable tyre on it and also I wanted the bearings.

It was a serious nightmare and I now truly appreciate just how strong nylon is. I had to go full cowboy with the drill to get the axle out of the rim. Removing the nut was ridiculously difficult considering I only had some pliers and clippers to work with. I knew I was going to lose the rim from the start (there was no alternative); but then I got stupid and thought I could de-glue the tyre from the rim even though I knew full well that I couldn’t in the way that I wanted to.

I ended up destroying the tyre; at least it wasn’t a good tyre and I still have a pair of rears and a single front remaining. I need to de-glue the rears with the acetone vapour method since all other methods I’ve tried thus far have failed. I wouldn’t have to de-glue them if they weren’t on pin style rims (I moved to rear hexes).

Anyway, here are some pictures of the destruction.

The spokes made it some much more challenging.

The axle after I got the nut and bearings off (you can see the stripped part on the left).

The nut started out looking something close to this (the exact one is in the first pic):

By the time I was done with it, it looked like this  :

:

Geez bro it’s called drilling out the stripped bolt  or were you trying to save that axle part?

or were you trying to save that axle part?

Something I’ve had surprising success with on stuck parts like that is heating up the outer part and spraying the inner axle in this case, with upside down compressed air (surprisingly the contraction/expansion is enough sometimes (though again I’ve never had to deal with tiny parts like that, typically at least 3/8" bolts)

Tried and failed, it’s a tiny surface.

No, I just wanted my bearings. I’m using a different type of axle now and have spares of the one that stripped.

Unfortunately in this case heat would make it worse as it was a nyloc nut with a rubber ring in it. Melting it would make it worse. These parts are tiny though. The axle is ~3mm. Also my issue was that both the axle and nut were stripped and the remaining threads on the axle were keeping the nut down.

This is the second or third time I’ve had stuck hardware on this truck and every time it has been a total pain. The first time it happened it was a pair of tiny button head screws that stripped out. It took a solid 3 mins of drilling with my dad’s good drill and drill bits to get through a single screw.

Damn, I feel for you then haha small parts are a PITA to begin with

You got the job done haha

If I needed for the parts to survive I would have just swapped back to my old front hubs when I wanted to use those parts. I just wanted my bearings.  But yeah, I hate working with small parts like this too.

But yeah, I hate working with small parts like this too.

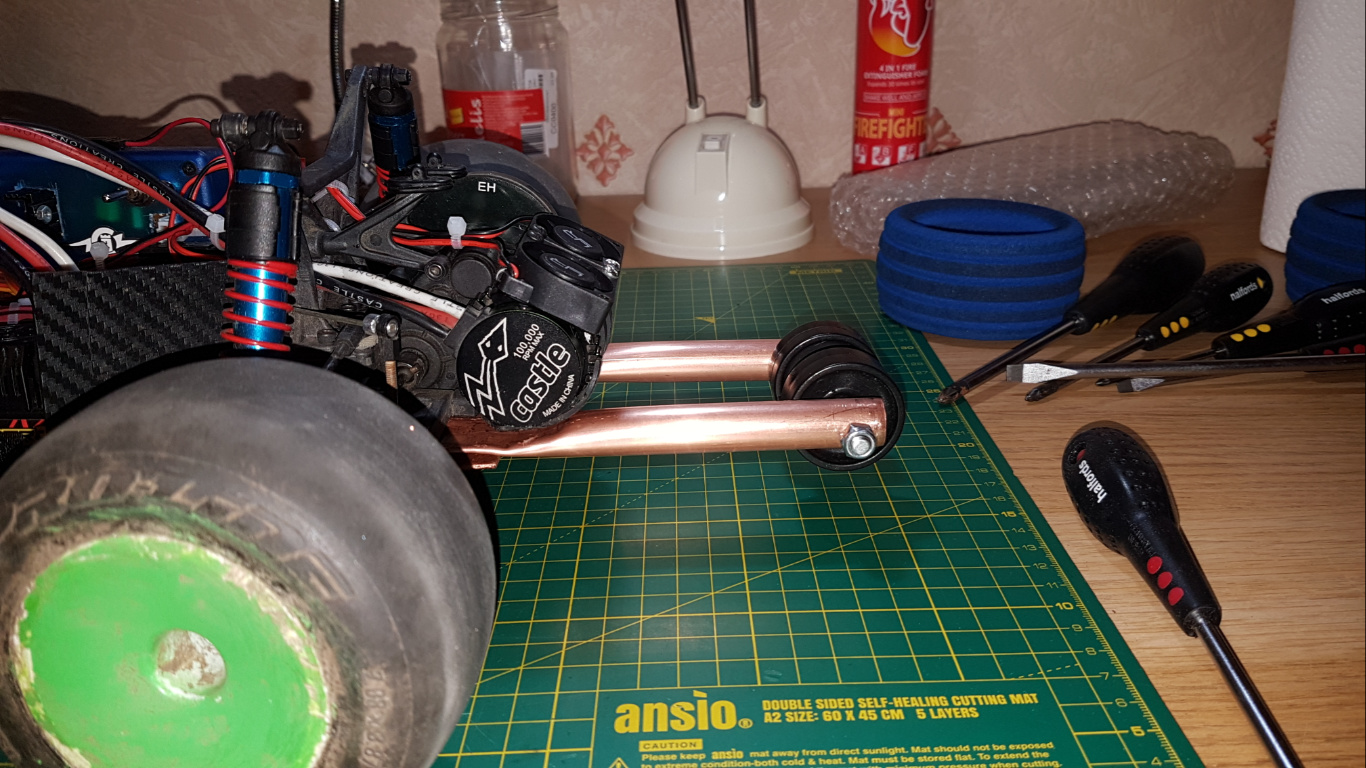

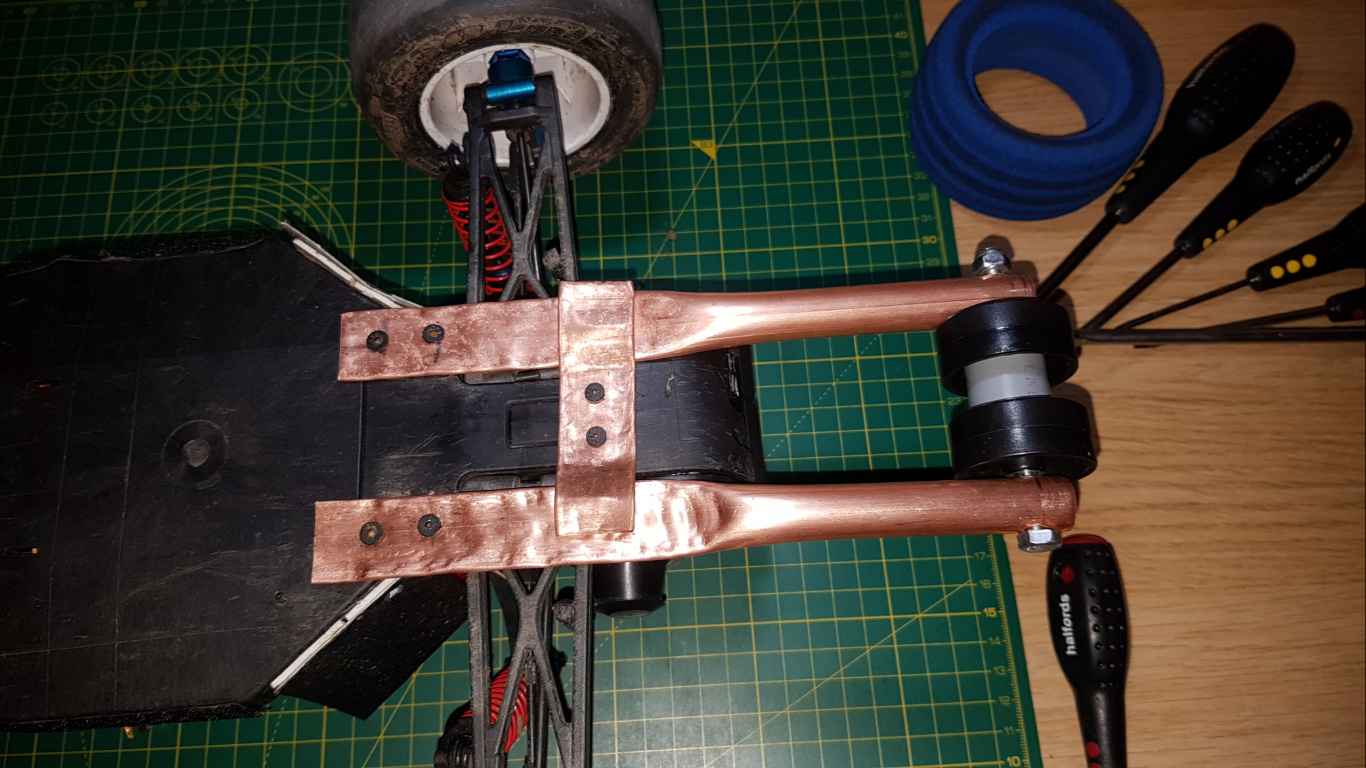

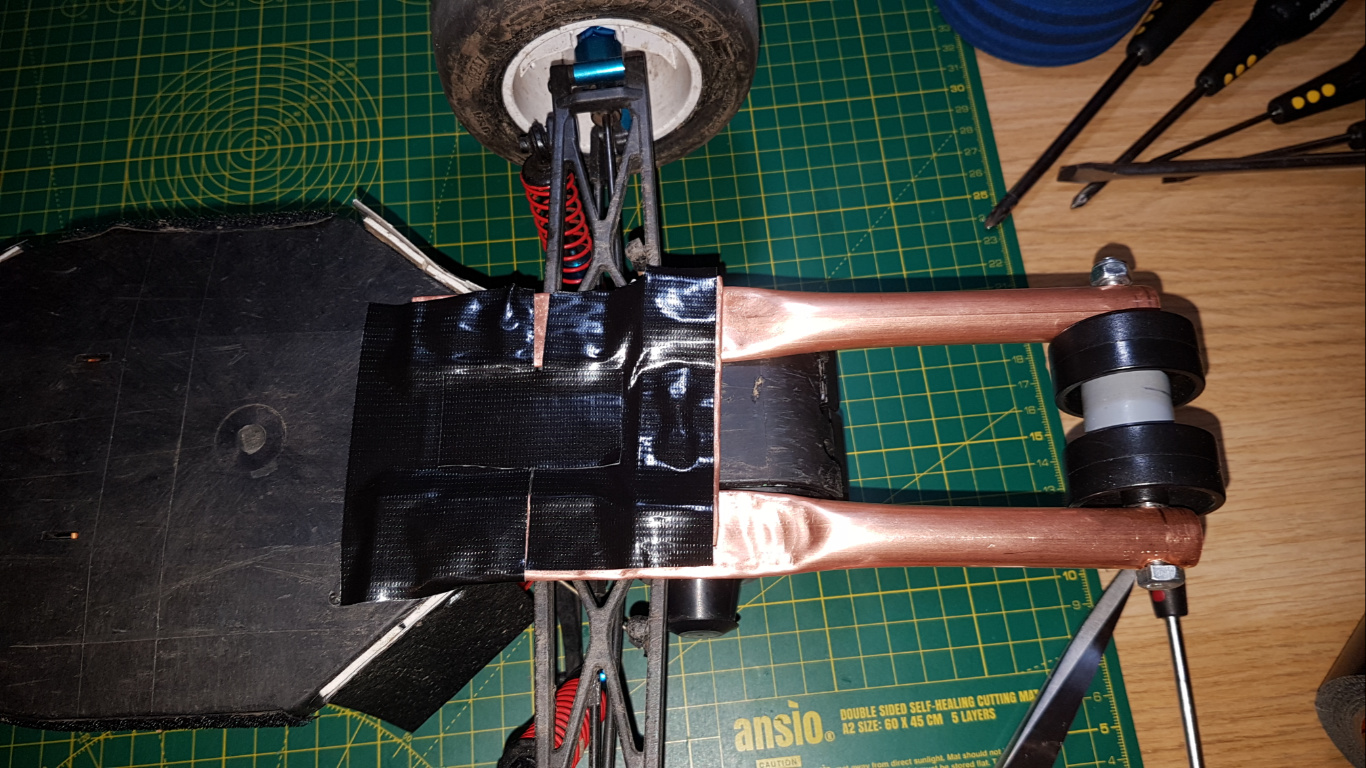

Ok, so the first prototype of the wheelie bar is complete. It really is as crude as it looks. We made it in 20 mins using scraps we found in the garage. Me and my dad don’t have high hopes for it but it was somewhere to start.

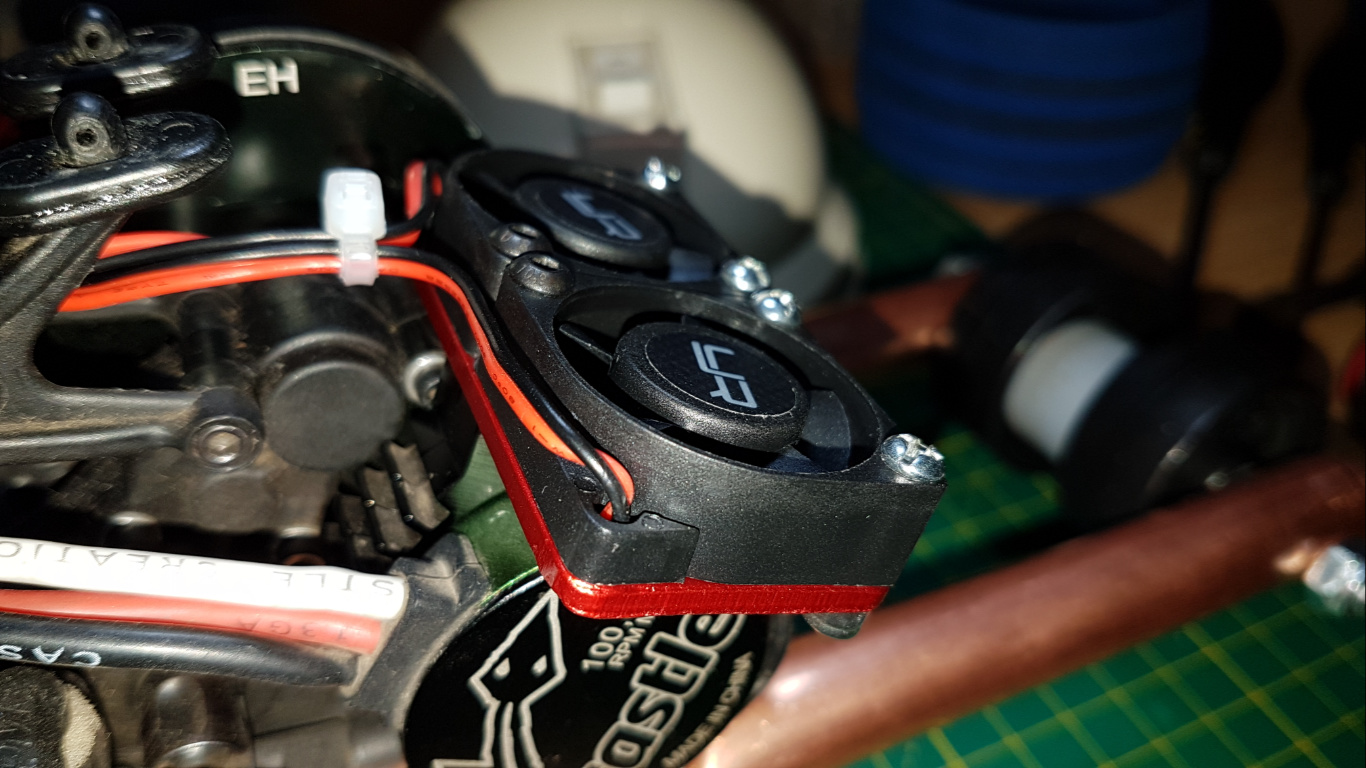

I’m also now permanently running the better motor fan mounting plate.

All that’s left now is to devise a camera mount and to tape my new tyres when they come in. I won’t actually be using them for a while since my current set is almost new (they only have a few runs on them).

The first couple pics remind me of Batman’s Tumbler. The way the front wheels seem to be positioned on the inside instead of the outside of the car.

That would be the world’s shonkiest tumbler replica

Hahaha would be cool though if you could replicate it!

That’d be too difficult. When they were building the real thing, the movie people gave the designs to an American company that specialises in cars for films and they said they couldn’t do it because it was too complex, so they gave it to the Brits instead  .

.

Happy to see that banshee got new heels- and always when I catch up here I feel the passion you have for the things you do! You are an engeneer with heart- body and soul! Gives me joy to read and see this

I hope the new heels will do their duty! And great your dad joins you doing this! I guess you maybe have the passion for this stuff from him? To create own stuff to solve problems I mean?! Looks like you two had a great time- looking forward to your report about the testing of your construction- good going with it

Heeeeeeyyyyyy…

valid point

valid point

WB-P1 (Wheelie Bar - Prototype 1) Post Run Report 1:

Run one was a success, the bar works just fine for now. It makes a clattering noise when it hits the ground (obviously) and it sometimes hits the ground on ascents but for now all is fine. With a bit of luck I won’t actually have to design a better version and just use this one regardless of how crude it is. It should perform even better with taped tyres, the current ones destabilise it a little when they start to balloon. Unfortunately I have no run footage as I still haven’t sorted out the new camera mount.

I do however have another issue now, this is with the transmitter. I noticed it from the first run but I chalked it up to me being unfamiliar with the feel of the new one. However, 3 or 4 runs later and I’m definitely noticing an issue. A friend in uni also noticed it when he did a few laps around the lab.

The issue is that the truck becomes totally oblivious to throttle input after even a slight dab of brake for a good 1-2 secs. You can squeeze the trigger to full throttle in that dead zone and nothing will happen until it suddenly wakes up again.

I have 2 theories as to what could be causing it.

-

The ESC’s settings where reset when I calibrated the system to pair the new Tx/Rx combo and it now has the 1 sec gap setting back in place. But the issue is that the 1 sec gap setting is for when you are going from forward into reverse, not the other way (I’m going the other way).

-

I’ve bought a dodgy Tx/Rx and will have to deal with it since I don’t want to faff about returning it.

With a bit of luck it will just be the ESC needing reprogramming and not the actual transmitter being at fault. I’ll report back in the coming days with any updates.

Quick question for @AJ_7 and @lpfan61 :

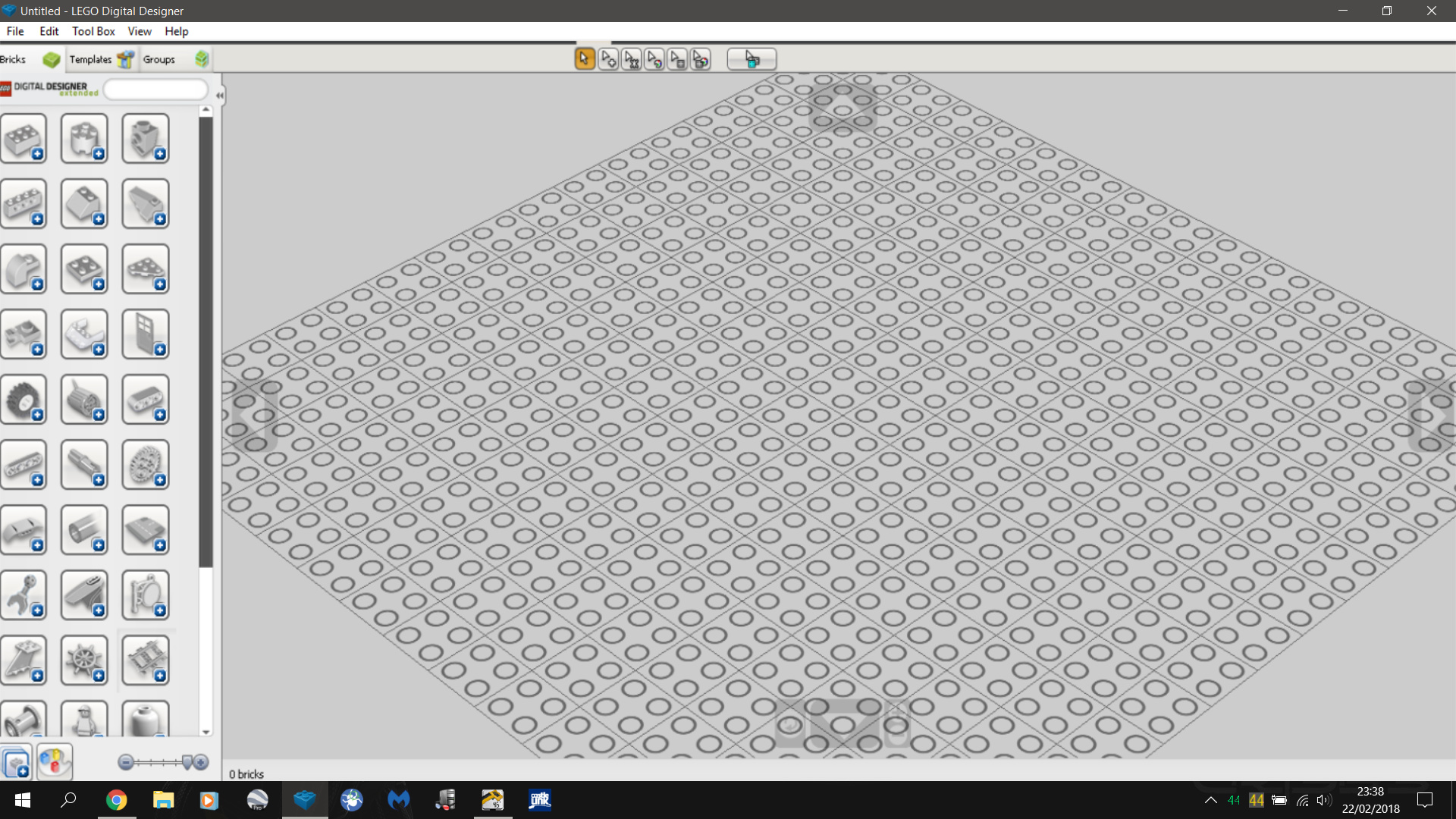

When you open LDD does it tell you that it can’t connect to the internet? Also is the top toolbar (with the hinge, bend, etc… tools) off of the screen for you? Because on my old laptop it won’t access the internet, on my new one it won’t fit on the screen regardless of all settings I’ve gone into.

EDIT: Ok, I reinstalled the one on my old laptop and it’s fine now. The new one is still off of the screen and the mouse cursor isn’t aligned with where buttons are on the screen. This is very annoying. I guess I’ll have to use LDD only on my old laptop.

Yes,it does but I click on ok and it works…

No,it’s part of the ldd “work table”…anyway you can check in some pics I posted here…

Uumm…that’s difficult for you to place/align the pieces this way…

That’s for offline mode. If you hit retry multiple times and it still gives you the error you might have to reinstall.

This is what I see. Note that all the sides are clipped and part of the top is missing completely.

where’s the tool bar?? How do you manage to use the tools? Anyway I have w7 on my pc…maybe it’s the reason to have a different arrangement…?

where’s the tool bar?? How do you manage to use the tools? Anyway I have w7 on my pc…maybe it’s the reason to have a different arrangement…?

EDIT: sorry for the late reply…I went to sleep yesterday…

So sorry! I was sleeping too. It says it can’t connect to the internet but the toolbar is fine, it’s on screen

Exactly, it’s off the screen.

I don’t. This is on the new laptop. I usually use keyboard shortcuts but this is annoying.

No, my old laptop ran W10 as well.

I know, I wasn’t expecting an immediate reply